Current Research

Environmentally Assisted Cracking

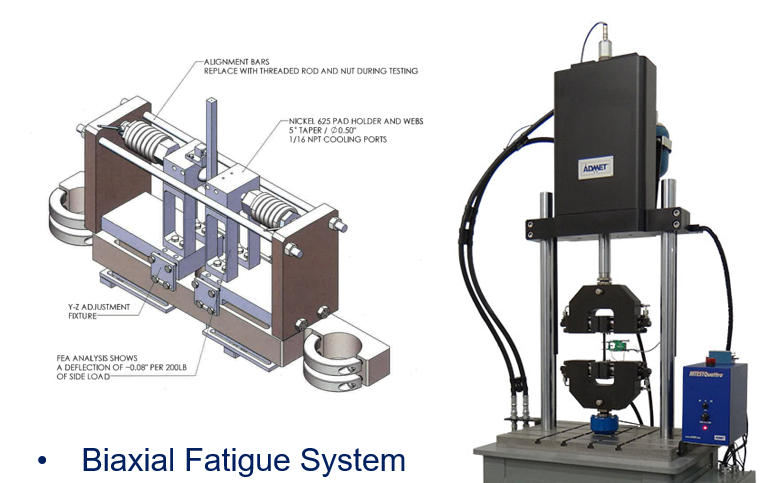

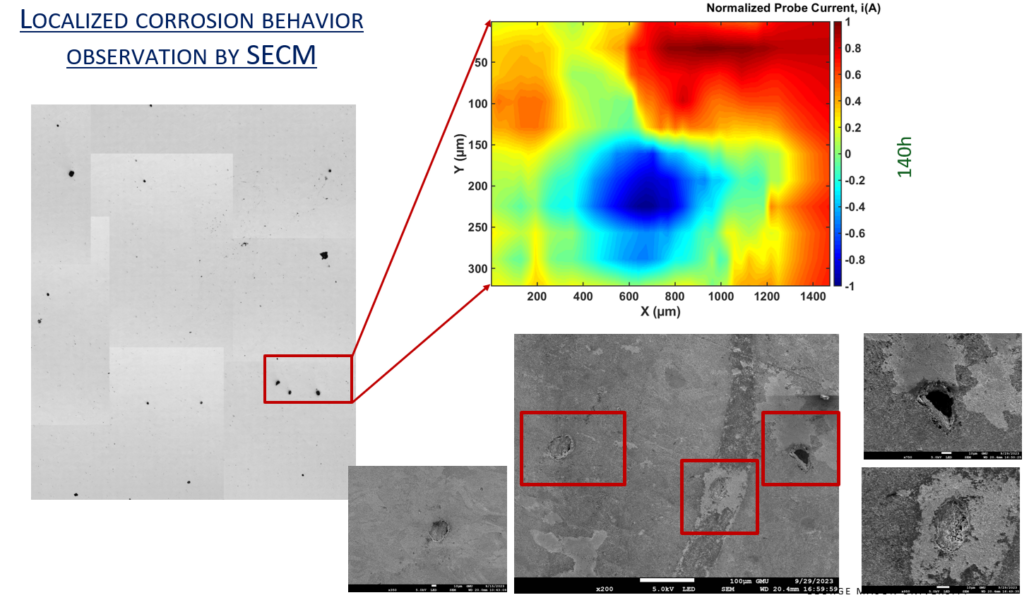

Crack Tip Electrochemical Response in EAC: While macroscale (or bulk) electrochemical techniques, such as cyclic polarization and electrochemical impedance spectroscopy, have been utilized in corrosion for decades, the translation of these techniques into microscale (or local) resolutions is an inherently complex process. In the world of corrosion research, very rarely (if at all) is the corrosion process considered to be a uniform process on a macroscale. For this exact reason, there has been a push to focus on the microscale processes occurring during corrosion. Scanning Electrochemical Microscopy (SECM) is a unique technique for corrosion for detecting diverse reactive species and corrosion products. It includes an Ultra MicroElectrode (UME) probe with 10µm Pt wire. The probe approaches the surface from bulk solution to a close proximity (<5µm) and collects corrosion current. It then generates approaching (or feedback) curves. These curves are either decreasing in current, for an insulative surface, or increasing for a conductive surface. The approaching curves are good indicators of local electrochemical reactivity of the surface. We performed SCEM scan and in feedback mode at the fatigue crack tip. Figure below shows a scan map of a compact tension specimen at fatigue cycles of 50 and at 978 N maximum load. The color bar provides a qualitative representation of the tip current. Notably, the current is lower for the region close to the notch tip despite a higher plastic strain in this region. This discrepancy arises from the out-of-plane deformation in this region and from the fact that the SECM probe is sensitive to the distance from the specimen surface. As a result, the tip current is lower in this region. Given the out-of-plane deformation ahead of the notch tip, an SECM line scan or area scan at constant probe-to-surface distance does not produce useful results. Thus, the approach curve method is adopted for this purpose. In the approach curve method, the position of the probe does not change in the plane parallel to the specimen surface, instead the probe-to-surface distance decreases incrementally, starting from the bulk solution. This method can be used to investigate the kinetics of the reactions occurring at the specimen surface which are not easily measured by bulk electrochemical methods such as Tafel tests.

Fatigue of Additively Manufactured Superalloys

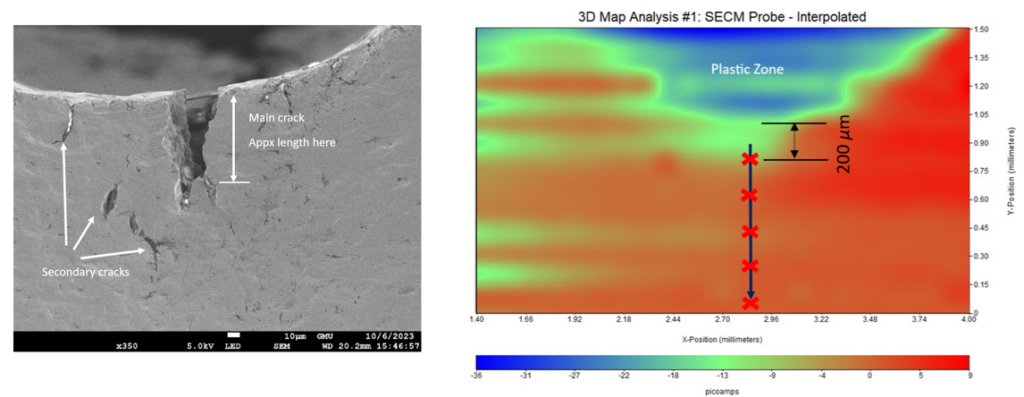

Additive manufacturing (AM) offers advantages for producing large, complex parts, such as reduced material waste, shorter lead times, and a lower buy-to-fly ratio. Wire Arc Additive Manufacturing (WAAM), with its high deposition rate and lower feedstock cost, is particularly suited for industrial applications. Haynes ® 233, a nickel-based superalloy from the Ni-Co-Cr-Mo-Al system, was recently introduced by Haynes International Inc. As a newly developed alloy, data on its mechanical properties is limited. This study investigates the microstructure, tensile, and fatigue properties of heat-treated (HT) WAAM Haynes ® 233 and compares them to its wrought counterpart. Yield strength (YS), ultimate tensile strength (UTS), and fatigue strength of WAAM Haynes ® 233 are 709.4 MPa, 890.1 MPa, and 253.8 MPa, respectively. These values indicate a 63.8 % increase in YS, a 1.11 % decrease in UTS, and a 21.7 % increase in fatigue strength compared to the wrought material. The slight decrease in UTS is attributed to process induced defects, while the improved fatigue strength in the HT material is due to the increased volume fraction and spatial distribution of carbides in the microstructure. Fractography of the tensile fracture surfaces indicated ductile failure in the wrought material and brittle failure in the HT WAAM material, with defects acting as initiation sites for fatigue failure in both materials.

Data-Driven Fatigue

With the increasing interest in utilizing additive manufacturing (AM) for fatigue-critical applications, reliable fatigue analysis tools are increasingly necessary. Unlike traditional manufacturing processes, AM involves a greater number of process parameters and manufacturing variables which adds complexity to the development of mechanistic fatigue models. Data-driven models, to some extent, have shown predictive capabilities for the fatigue properties of AM alloys. However, no study has extensively investigated fatigue properties across different AM alloys with the aim of developing predictive models for fatigue databases. A data-informed knowledge discovery framework is developed for exploring diverse AM fatigue datasets in the literature. Characteristics of the AM fatigue datasets are first analyzed within this framework to uncover data-driven insights for machine learning modeling. Machine learning techniques are then used to solve classification and regression problems using fatigue ratio as the property of interest. k-nearest neighbors and support vector machine classifiers are used to classify process parameters and manufacturing variables to determine the class of fatigue ratio they belong to based on a pre-defined threshold. Similarly, a Gaussian process regression (GPR) model is used to predict the fatigue ratio of AM alloys with a 95% prediction interval. The Shapley Additive exPlanations (SHAP) method is used to explain the predictions of the GPR model. This framework is validated using Ti–6Al–4V, IN718, and AlSi10Mg datasets from the literature. The proposed framework efficiently maps process parameters, post-processing sequences, and AM types to the fatigue ratio, thereby providing an efficient surrogate modeling methodology for estimating fatigue properties from available datasets.

Computational Mechanics

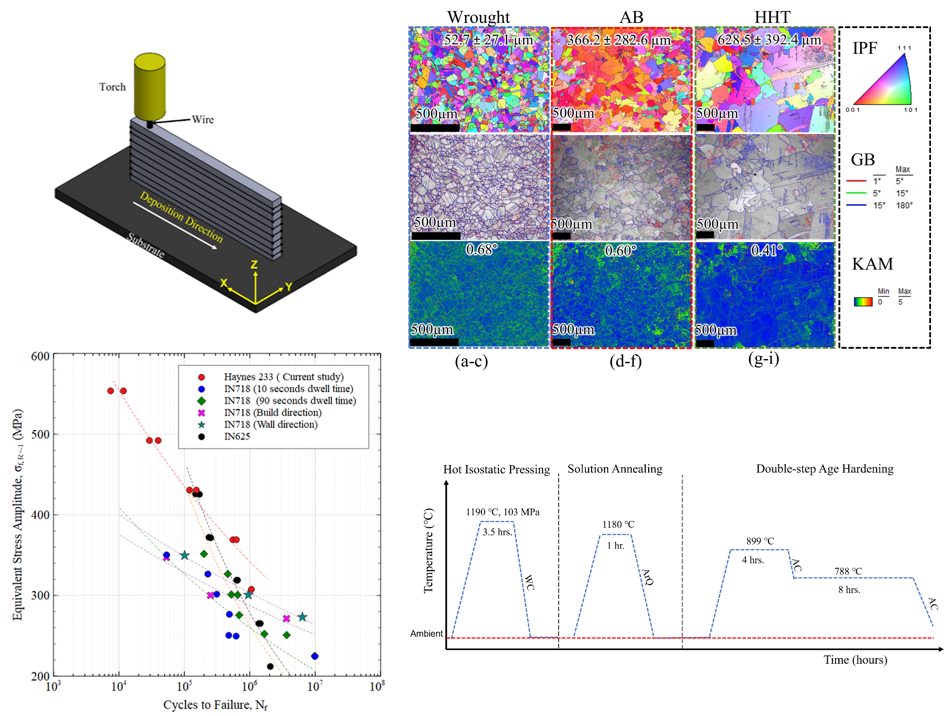

At RMFLab, we use advanced physics-based computational modeling and data-driven tools to model mechanical and electrochemical behaviors of materials at multiple length scales. These approaches include, finite element phase field method, crystal plasticity, density function theory, and machine learning approaches.

Corrosion of Additively Manufactured Alloys

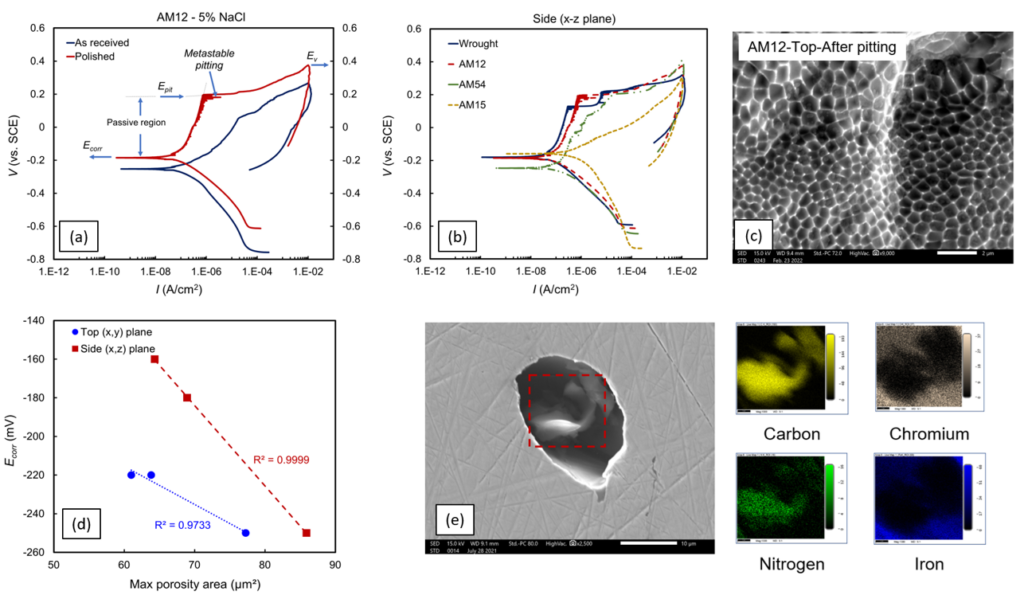

This study investigates the impact of process-induced defects such as gas pores, lack of fusions, and surface roughness on corrosion behavior of stainless steel 304L (SS304L) fabricated by laser powder bed fusion additive manufacturing. Specimens are printed with optimized process parameters but selected from different locations on the build plate. Parallel and perpendicular surfaces to the build direction are investigated and compared with corrosion properties of wrought SS304L in 5 wt% NaCl. The results reveal significant difference in corrosion behavior among specimens due to variations in their defect features. Pitting potential, pit initiation, and growth rates are found to be influenced by specimen location on the build plate. The specimen located in downstream of the shielding gas flow shows the least corrosion resistance. While no clear trends are observed between some corrosion properties and defect features, other properties show strong correlations. For example, no trend is observed for the corrosion properties in relation to pore average area fraction. However, strong correlations are observed for the corrosion properties as functions of defects maximum area. Corrosion properties linearly deteriorate as the defects maximum area increases. Roughness shows a mixed relationship with pitting potential. Comprehensive discussions on all these effects are presented.

Atmospheric Corrosion

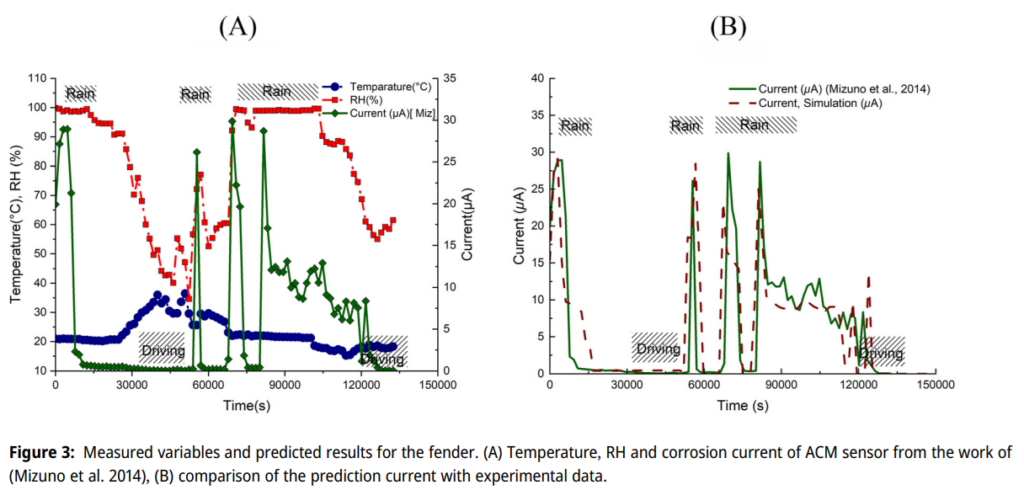

To address the need for reduced vehicle weight and improved environmental sustainability, the automotive industry has increasingly turned to mixing lightweight materials and alloys with metal alloys. However, this integration of dissimilar materials has heightened the risk of galvanic corrosion. This study addresses the gap in modeling of galvanic corrosion under dynamic thin film electrolyte by incorporating data derived from real-world weather conditions and finite element simulations. The presented model successfully captures the trend of galvanic corrosion rate for a given atmospheric environmental condition. The model predictions are compared with experimental data in the literature. Good agreements are observed. The model is further used for prediction of galvanic corrosion of two identical vehicles located in two different geographic locations (i.e., Miami Beach in Florida and Wendover in Nevada) in the year 2021 leveraging weather station data. Additionally, a Bayesian estimation method is used to account for uncertainties in the model parameters and estimation of the probability of failure.

Corrosion Measurement: Localized vs. Bulk

Corroding surfaces react to the electrochemical potential and the chemical composition of the solution in which they are in direct contact. While bulk (macro) electrochemical analysis provides average corrosion response of the exposed surfaces, the local (micro) electrochemical analysis methods provide grain scale corrosion response which is most relevant to materials with heterogeneous microstructural features such as AM metals. The unique microstructural features of AM metals along with complex electrochemical potential and chemical composition of the solution that occur in occluded regions such as pits and cracks have made it difficult to fundamentally understand the corrosion process that locally occurs in these regions especially under mechanical stresses. The overarching goal of this research is to advance our ability to fundamentally understand the synergy between corrosion and mechanical stresses of environmental cracks, relating the local electrochemical processes to microstructural at the crack tip. Localized electrochemical techniques, such as scanning electrochemical microscopy (SECM), provide the spatial resolution required to study localized corrosion events, for example, at defects. The SEM images of defects following 140h of exposure during SECM testing and subsequent etching are presented in figure below. The regions surrounding each defect, which exhibit varying levels of corrosion activity over time, reflected in the temporal changes in the UME tip current. These observations provide compelling evidence that a different corrosion attack predominantly takes place within the defects due to presence of active and passive regions in their vicinity

High Temperature Fatigue

With the increasing interest in adopting additively manufactured (AM) IN718 for high-temperature applications, driven by the design and manufacturing flexibility offered by AM technologies, understanding its fatigue performance is crucial before full-scale adoption. In the fatigue crack initiation stage, discrepancies in low cycle fatigue (LCF) and high cycle fatigue (HCF) life performances are observed in the literature. Some studies have shown that the average room temperature fatigue life of AM IN718 is superior or comparable to that at high temperatures in the LCF regime. Conversely, in the HCF regime, high-temperature fatigue life is sometimes found to be superior to that at room temperature. However, other studies indicate no clear trend regarding the effect of temperature on the HCF life. Although various mechanisms have been proposed to either improve or degrade fatigue performance across the LCF, HCF, and very high cycle fatigue (VHCF) regimes, the underlying reasons for the distinct behaviors in these regimes remain unclear. Competing mechanisms, such as surface oxide formation and thermally driven dislocations glide, can potentially enhance or reduce fatigue life. However, the interaction and control of these mechanisms over the fatigue strength of AM IN718 are not yet fully understood. Microstructural investigations have suggested that controlling the formation and precipitation of deleterious secondary phases is crucial for tailoring the high-temperature fatigue strength of AM IN718. Therefore, it is imperative to design heat treatment protocols informed by a comprehensive understanding of phase formation kinetics to improve the high-temperature fatigue performance of AM IN718 compared to their traditionally manufactured counterparts. This is particularly important for IN718 parts manufactured using directed energy deposition technology, which currently lacks standardized heat treatment procedures.