At RMFLab we use a variety of techniques to understand the multi-scale mechanical and electrochemical behavior of metals. Our facilities are designed for ex-situ and in-situ electrochemical and mechanical characterizations.

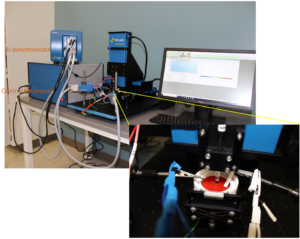

Scanning ElectroChemical Microscopy (SECM) Station

Scanning ElectroChemical Microscopy (SECM) is a Scanning Probe Microscopy (SPM) technique, which measures the local activity of a sample. Unlike other SPM techniques the local activity of SECM shows chemical selectivity due to its use of a redox mediator. SECM is the most popular Scanning Probe Electrochemistry technique. As with other techniques in this family SECM it can be used to gain further insight into the electrochemistry occurring at the bulk level. SECM differs from other Scanning Probe Electrochemistry techniques because it does not have an activity requirement. As a result, SECM can measure anything from a fully insulating to a fully conducting sample, making it applicable to a wide range of systems.

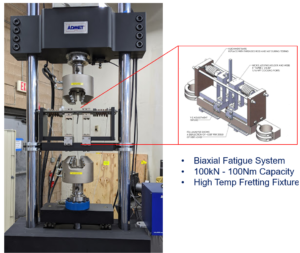

Biaxial Fatigue Machine with High Temperature and Corrosion Capabilities

The biaxial fatigue machine has capability of 100kN axial and 100Nm torsional. It is equipped with a high temperature fretting fatigue fixture. The axial load frame works with a hydraulic pump which the torsional frame is powered electrically. A variety of tests including, low-cycle and high-cycle fatigue, bi-axial fatigue, high temperature fretting fatigue, corrosion-fatigue, and fatigue crack growth tests can be performed.

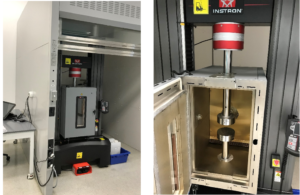

Battery Abuse Testing Facility

Equipped with a fire proof walk-in fume hood, this Instron machine is used to perform thermo-mechanical abuse testing on batteries. The environmental chamber is used for a wide range of temperature: -80oC to 350oC while test artifacts are under mechanical loading. Variety of cross heads are available for performing mechanical testing to understand the mechanisms that lead to energy storage system safety and reliability incidents.

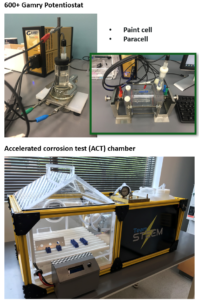

Corrosion Testing Facility

The Gamry 600+ potentiostat is a high-performance, research-grade potentiostat/galvanostat/ZRA designed for fast, low-current measurements. It does well for a variety of applications such as physical electrochemistry (especially at microelectrodes), fast cyclic voltammetry, electrochemical corrosion, electrochemical noise measurements, paints and coatings, and sensors.

The PainCell and ParaCell™ Electrochemical Cell Kit are available for convenient mounting of a wide variety of flat samples. The cell is designed so that large and bulky samples can be accommodated on either end for experiments involving two electrodes such as galvanic corrosion or electrochemical noise.

A custom-built accelerated corrosion test (ACT) chamber is available for performing atmospheric corrosion testing. The chamber is compact, light weight, table-top, and fully automated with no need for lid opening.

Programable: ASTM B117, MIL-STD-810 method 509.

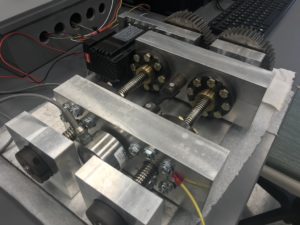

In-Situ Micro-Fatigue Testing Device

A custom-built fatigue testing device is available to carry out fatigue tests on sub-sized specimens in-situ under scanning electron microscope (SEM). The micro-fatigue tester is used to perform fatigue tests, corrosion-fatigue and stress-corrosion tests on sub-sized samples. A 2D digital image correlation (DIC) facility is also available to measure deformation of sample.

Microscopy (at shared facility)

- Optical Microscopy and metallography station

- SEM/EDS/EBSD JEOL JSM 7200/EDAX

- SEM/EDS/EBSD JEOL JSM IT500HR/EDAX

- TEM JEOL JEM-1400

High Performance Computing (HCP) Facility

The PI and his students have access to the high-performance computing (HPC), ARGO Cluster at George Mason University. ARGO is a batch computing resource available to all faculty and their students at George Mason University.

Direct Energy Deposition Metal 3D Printer (shared facility)

The Meltio M450 allows users to produce metal parts of very high density in a single-step process on a very compact footprint. The printer is capable of printing dual wires for multimaterial printing studies.